A smart helmet combines the traditional safety structure of a hard hat with built-in technology designed to improve productivity, communication and especially safety on busy jobsites.

Historically, electronic devices didn’t hold up well on construction sites, where dust, impact and debris could quickly damage consumer electronics. However, today’s smart helmets are built for tougher environments, protecting both the wearer’s head and the technology inside. This advanced wearable tech uses built-in sensors and augmented reality (AR) features to help crews work more safely and efficiently. Here’s what to know about smart helmets, how they work and the features that matter most on today’s jobsites.

What is a smart helmet?

Smart helmets are hard hats with built-in technology designed specifically for construction workers. Depending on the make and model, smart helmets can include features like impact detection, real-time health monitoring, early warnings that help employees avoid dangerous situations, data visualization, and livestreamed audio and video.

Clark Lowe, president and CEO of the O’Connor Co., a North Carolina-based construction firm, said adopting smart helmets can improve safety and reduce workplace accidents. According to Lowe, smart construction helmets can even replace multiple pieces of personal protective equipment (PPE).

“Traditionally, employees may have a helmet for eye and ear protection, and keeping track of all the equipment can be a pain,” Lowe explained. “Having all this protection fixed to the helmet makes employees more likely to use the PPE.”

While specific regulations vary, all states require construction companies to hold the appropriate

contractor licenses that align with the scope of work being performed.

What are the features of smart helmets?

Smart helmet features vary by model, but most focus on safety and data collection. Here are some of the helpful functions you might find on smart helmets.

Health monitoring

Smart helmets may allow you to monitor workers’ vitals to help ensure they stay safe on the job. This technology can provide early alerts about potentially hazardous conditions or environments and may flag when a user shows signs of fatigue that could affect performance. Data is typically tracked in real time and accessed through a central dashboard.

Hands-free visual data

Working in tight spaces or at height while carrying devices like tablets can create safety risks. Some smart helmets address this by projecting critical information, such as Building Information Modeling (BIM) data, onto a visor or monocle display. This setup lets workers view information without taking their hands off the task.

Proximity safety

People working on construction sites or around heavy machinery face a significant risk of accidents. According to the Bureau of Labor Statistics, the construction industry recorded 1,075 fatal work injuries in 2023, the highest total of any industry sector. To help address these all-too-real risks, some smart helmets include forward- and rear-facing depth-sensing cameras that can alert workers when they get too close to equipment or obstacles. These alerts trigger an audible or visual warning that may help reduce collisions and give workers critical extra seconds to react, which can improve safety outcomes on busy jobsites.

Data overlay

Data overlay or visualization gives workers access to real-time information, reducing the need to travel back and forth to computer terminals. For example, if a worker needs to restart a system or piece of machinery, they don’t have to return to the office for a status update; they can view it directly through the smart helmet’s visor.

Another way to use this feature is by integrating it with construction estimating software or construction asset management platforms, which can track labor, equipment usage and project data while teams are on the go.

Many construction management platforms now offer cloud integration, allowing data captured by smart helmets to sync with project dashboards for near real-time cost and timeline visibility.

Thermal vision

Thermal vision can improve worker safety by helping crews visualize, record and analyze temperature changes in their immediate environment.

Guided work instructions

With intuitive AR guidance, smart helmets can display processes or tasks that need to be completed and how to perform them. Supervisors can also send instructions from a central system directly to a worker’s visor.

Live support

Serious problems can arise if a worker attempts a task they aren’t trained to perform. Waiting for an expert to arrive on-site can slow progress, so some smart helmets include remote support features that let workers make or receive calls through their visor. In some cases, remote specialists can provide visual guidance to help walk a worker through a task.

Data collection

Outfitting workers with smart helmets gives companies another way to collect real-time information about what’s happening on a jobsite. Data from sensors and health monitoring tools can help supervisors spot potential safety issues early, while usage data may reveal where crews are slowing down or need additional support.

Augmented-reality blueprints

Using AR, built-in cameras and sensors, smart helmets can help workers visualize project data directly in their field of view.

“There are a few smart helmets available in the market space that offer features like augmented reality displays,” said Yaeir Moinzadeh, a licensed contractor and owner of Blue Rise Roofing in Baltimore. “Using such features, workers can complete tasks more accurately and efficiently.”

Some teams use

virtual reality technology during preconstruction to review a site layout or run through complex tasks before anyone steps onto the project. It’s another way to catch safety concerns early and give workers a clearer picture of what to expect once the job begins.

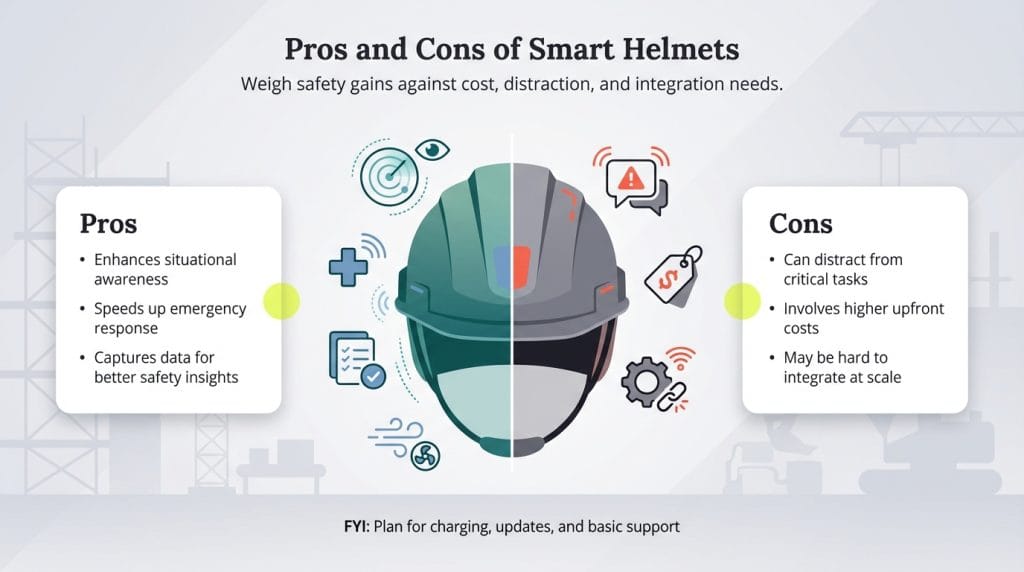

What are the pros and cons of smart helmets?

As with any tool, smart helmets come with both benefits and tradeoffs. Here are a few of each.

Pros of smart helmets

- They enhance situational awareness. Smart helmets include safety features designed to help workers stay aware of their surroundings. Some models use sensors to detect sudden head movements, monitor nearby obstacles and alert users when conditions may pose a risk. In certain cases, helmets can issue warnings if a worker is moving too quickly or entering a potentially hazardous area.

- They enable rapid emergency response. If an accident occurs, a smart helmet may alert nearby workers or supervisors. Some models connect to Wi-Fi or cellular networks to share a worker’s location or send a distress signal so teams can respond more quickly.

- They facilitate accurate incident reporting. If a worksite accident happens, built-in cameras and sensors can capture information about the event, helping teams review what occurred and identify potential safety improvements. Data recorded by the helmet may support incident investigations and training efforts after the fact.

- They improve long-term wearability. Many smart helmets are designed with adjustable fits and improved ventilation, which can make them more comfortable than traditional hard hats. Lowe and Moinzadeh noted that customizable designs may encourage workers to wear protective equipment more consistently throughout the day.

Cons of smart helmets

- They present potential distractions. Smart helmets, like phones or other connected devices, allow users to listen to music and communicate with others, which may affect focus if not used carefully. For workers driving vehicles or operating machinery, distraction is an important factor to consider when introducing new wearable technology.

- They require a high upfront investment. While smart helmets offer clear advantages, their cost can be a barrier for smaller firms. High-end AR-enabled headsets can cost several thousand dollars per unit. According to Lowe, a smart helmet “fully equipped with all the bells and whistles” can cost more than $1,000.

- They face implementation and compatibility hurdles. Even as availability improves, integrating smart helmets into existing workflows can be challenging. Companies must ensure the hardware works with current project management tools and safety procedures. On long shifts or remote sites, charging needs and weak connections can make smart helmets tougher to roll out than traditional hard hats.

Like most connected devices, smart helmets need regular charging and occasional software updates. Some companies assign a supervisor or IT contact to manage batteries, connectivity and basic troubleshooting so workers aren’t slowed down during a shift.

What is the best way to incorporate smart helmets into your construction company?

As more construction teams begin testing wearable tech on jobsites, smart helmets are becoming a more practical option rather than a niche experiment.

For construction businesses looking to incorporate smart helmets into their operations, Moinzadeh recommended starting with a pilot program and exploring partnerships with manufacturers that can offer training and ongoing support.

“Business owners can begin by equipping a small team with smart helmets and, afterward, collect their honest feedback regarding its effectiveness,” Moinzadeh advised. “By following this approach, you can understand the benefits and challenges before making a larger investment.”

Source interviews were conducted for a previous version of this article.