Workplace accidents carry a heavy price tag for businesses and teams. According to 2023 National Safety Council data, work injuries cost an astounding $176.5 billion, including $53.1 billion in lost wages and productivity and $36.8 billion in medical expenses. The good news is that prevention is well worth the effort. The Occupational Safety and Health Administration (OSHA) says employers could save $9 billion to $23 billion each year in compensation costs by making safety a priority.

And while construction sites and factory floors may seem like the most obvious danger zones, the truth is that accidents can happen anywhere — even in a quiet office cubicle. That’s why every business needs to know how to prevent workplace accidents and how to respond when one occurs.

What constitutes a workplace accident?

A workplace accident is any unplanned event that causes injury or illness to an employee while they are carrying out their job duties. These accidents can happen on the employer’s premises, at an off-site job location or even while traveling for work. They may involve physical harm (such as slips, trips, falls or equipment mishaps) or mental harm, like trauma caused by workplace violence or severe stress.

What matters is that the injury or illness arises out of the employee’s work activities, not from personal circumstances.

Workplace accident vs. occupational disease

It’s easy to confuse workplace accidents with occupational diseases, but the two aren’t the same. A workplace accident is a sudden, unexpected event that injures or sickens an employee while they’re doing their job. An occupational disease, on the other hand, develops slowly over time as a result of ongoing exposure to certain work conditions. Knowing the difference is important because it affects how responsibility and compensation are determined.

Editor’s note: Looking for the right worker’s compensation insurance for your business? Fill out the below questionnaire to have our vendor partners contact you about your needs.

Workplace accident examples:

- A receptionist slips on a wet floor in the break room and sprains an ankle.

- A machine operator injures a hand after getting caught in equipment missing a safety guard.

- A worker falls from scaffolding because of inadequate fall protection.

Occupational disease examples:

- A janitorial worker develops chronic back problems after years of heavy lifting.

- An employee exposed to asbestos develops a related illness many years later.

Workers’ compensation laws vary by state, but in general, employers must cover an injured employee’s medical expenses and lost wages after a workplace accident through

workers’ compensation insurance.

How can a business owner best reduce the risk of injuries in the workplace?

According to the Bureau of Labor Statistics, U.S. employers reported 2.6 million workplace injuries and illnesses in 2023, along with 5,283 fatal work injuries. That equates to a fatal injury rate of 3.5 deaths per 100,000 full-time equivalent workers — meaning, on average, a worker died every 99 minutes from a job-related injury.

Some industries face greater risks than others. In 2023, construction businesses had more than 1,000 worker deaths. Transportation and warehousing recorded nearly as many fatalities, but their fatality rate was the highest of all major sectors. Agriculture, forestry, fishing and hunting had fewer deaths overall, yet the rate of fatal injuries was the highest compared to the size of its workforce.

Still, it shouldn’t take a tragic accident to persuade business owners and managers to change their workplace culture to prioritize employee health and safety. Follow the tips below to help prevent workplace accidents.

1. Carry out regular risk assessments.

Workplace risk assessments should be scheduled on a regular basis (at least twice a year) and anytime there are major changes to equipment, processes or staffing your business. In industries with higher accident rates, like construction, quarterly reviews are often more appropriate.

During a risk assessment, the goal is to identify hazards that could lead to injuries or illness. Important areas to review include:

- The equipment employees use

- The tasks employees must perform

- Training requirements

- Employee workloads

- Additional risks faced by workers who are older, pregnant or have disabilities

After your assessment, take these steps:

- Record all hazards and the threats they pose.

- List the specific actions employees must take to deal with those hazards.

- Create or update formal safety procedures to mitigate each risk.

- Reassess each danger regularly and update procedures as needed.

- Investigate and address new risks whenever you hire staff, change processes or move equipment.

Encourage workers to report if specific activities put them at greater risk. Building a culture of empowered employees who feel comfortable speaking up is critical. To make procedures more effective, interview employees in each role. Their firsthand knowledge of processes and machinery can reveal important risks and help shape safer practices.

2. Conduct physical assessments for demanding roles.

Some types of work are physically demanding and can be even more challenging for employees with certain health conditions or limitations. For example, someone with a history of back problems may be unable to work on a construction site or handle a lighting rig at a concert venue.

Many companies require prospective employees to complete physical and mental health screenings before they’re offered a position. Others require annual physicals if a role is especially labor-intensive. While this may seem intrusive, the purpose is to ensure the job does not put a worker’s health at risk.

3. Provide safety and wellness training regularly.

Implement mandatory safety training on a set schedule: orientation training for all new employees within the first week, refresher sessions every six months for existing staff, and immediate retraining whenever safety procedures change or after a workplace incident.

Show employees that health and safety are business priorities, and make your expectations for workplace behavior clear. Invest in employee training on all relevant health and safety instructions tied to each role, and retrain staff right away if new risks are identified during a risk assessment.

Wellness programs can also reinforce your commitment to employee health. These initiatives support both physical and mental well-being, helping create a workplace where employees are more alert, responsive and productive.

4. Hire qualified workers.

Some jobs require specific licenses, while others are better suited for employees with certain degrees and hands-on experience. During the hiring process, make sure prospective employees are truly qualified for the role. If a worker is less capable than they appear or lacks real-world training, they can put themselves and others at risk.

New employees are also more prone to injuries. Travelers’ 2024 Injury Impact Report found that workers in their first year on the job make up 35 percent of all workers’ compensation claims. This shows why a thorough onboarding process and training are so important.

5. Hire enough workers.

Accidents are more likely to happen if employees are tasked with too much. If you notice team members struggling with their workloads, take some of the pressure off by hiring more employees. If you don’t, your workers will be at a higher risk of accidents and employee burnout. Additionally, workplace absenteeism levels may be greater, which will only exacerbate the problem.

6. Keep workspaces clean and walkways clear.

A cluttered, unclean work area is inherently hazardous. Ensure staff members follow best practices, including running computer cables and power cords properly so they don’t create a tripping hazard. Other worthwhile efforts include storing equipment appropriately, cleaning up spills promptly and limiting eating to designated areas.

“In many cases, precautionary practices can prevent accidents,” said Marc S. Albert, a personal injury attorney.

7. Post proper signage.

Post signs in common areas and appropriate places to remind employees of proper safety procedures. For example, a poster in an office kitchen can remind people to mop up spilled drinks and put out a hazard sign when the floor is wet. In manufacturing areas, signs on entrance doors should remind workers to don their protective gear.

8. Provide adequate lighting.

When carrying out risk assessments, you should ensure that there’s plenty of natural and artificial light for staff members to see clearly when completing their work. Lighting is equally crucial outside the office. For example, parking lots, outdoor areas, walkways, entrances and exits must be properly lit. If an employee is injured on your property, it will likely still be your responsibility, particularly if the environment is considered unsafe.

9. Practice good vehicle maintenance.

Ensure all company vehicles are well-maintained and serviced regularly. Proper upkeep helps vehicles last longer, reduces costs over time and protects both employees and the public.

It’s also important that any employee who drives for the company understands how their vehicle operates and has the proper authorization to use it.

10. Provide staff with protective equipment.

It isn’t fair or safe to expect people to do their jobs without the right gear. From day one, make it a company-wide requirement to supply staff with the protective equipment their roles demand. Depending on the work, this could mean safety harnesses, gloves, goggles or masks. No one should ever be asked to perform tasks without proper protection.

The type of personal protective equipment (PPE) will vary by environment. Construction workers need hard hats, safety harnesses and steel-toed boots. In manufacturing, PPE often includes safety glasses, hearing protection and cut-resistant gloves. Even in office settings, employees benefit from ergonomic workstations and well-stocked first-aid supplies.

PPE also requires upkeep. Conduct monthly inspections to confirm all equipment meets current safety standards, replace worn items as needed and train staff to use their gear correctly. Managers should be responsible for addressing situations where PPE is not being used properly.

11. Require employees to dress appropriately for their roles.

Dress codes may have relaxed in many workplaces, but safety-related rules still matter. On a construction site, for example, certain footwear should be mandatory, and jewelry that can get caught in machines should not be allowed.

What counts as appropriate dress will vary by role, and it’s worth reviewing those requirements from time to time to make sure they still fit the work environment.

12. Discourage employees from taking shortcuts.

Many accidents happen when people cut corners, especially if they’re in a hurry or feel comfortable with a task. For example, a worker might climb without a safety harness because gearing up feels like a hassle. Shortcuts like these create risks that can lead to anything from minor injuries to life-threatening accidents.

What should you do when an accident happens in the workplace?

Even with strong safety measures in place, accidents can still happen. When they do, it’s important to respond quickly and correctly.

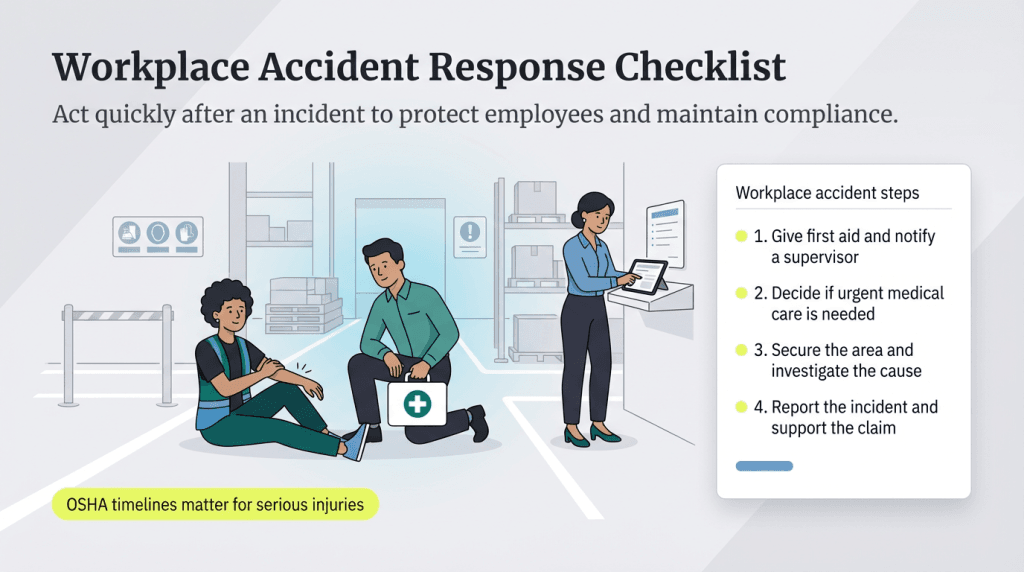

Understanding OSHA reporting requirements is essential. Employers must report any workplace fatality within eight hours, and any in-patient hospitalization, amputation or loss of an eye within 24 hours. In addition, employers with 100 or more workers in designated high-hazard industries must electronically submit detailed injury and illness data to OSHA every year.

Here are the key steps to take immediately after a workplace accident to protect your employees and your business:

1. Tend to the employee and report the accident.

Anyone who witnesses an accident should assist the injured employee right away. Determine what help they need and make sure it’s provided. If a manager isn’t already present, witnesses should notify leadership as soon as possible. Management must then document the incident in the company’s accident records.

2. Determine whether medical treatment is needed.

Use the office first-aid kit to treat minor injuries like scrapes or cuts. Keep in mind, though, that some injuries may seem small at first but worsen later. When in doubt, have the employee evaluated by a qualified onsite medical professional or transport them to the hospital. For head injuries, take extra care and avoid moving the worker until it’s medically safe.

3. Investigate the circumstances, and revisit your safety guidelines.

After the injured employee has been cared for, look at the area where the accident occurred and deal with any immediate hazards. Then run a new risk assessment to understand how the accident happened. Was a hazard missed? Was the employee not trained or supervised properly? Update your safety guidelines to fix any shortcomings and help prevent future accidents.

4. Assist with your employee’s claim.

Workers’ compensation rules vary by state. Most states give employees one to three years to file a claim, but the deadline to report an injury to the employer is much shorter — usually 30 days, and sometimes as little as 10. To stay compliant, check with your state’s workers’ compensation board or legal counsel for exact requirements.

Because the workers’ comp claims process is time-sensitive, accidents should be reported right away. Provide as much detail as possible when completing insurance forms, and gather any required documentation, such as witness statements. You may also need to send a copy of the injury form to your state’s workers’ compensation board.

In some cases, an injured employee’s needs may go beyond what workers’ comp covers. When that happens, encourage them to seek support from medical or legal professionals.

A

workers' compensation settlement may be necessary when employees suffer severe or permanent injuries. These settlements, whether lump sum or structured payments, account for both current and future medical and financial needs.

Why is it important to prevent accidents in the workplace?

Workplace safety goes beyond an obvious moral and ethical obligation. “Aside from your company’s moral obligation to provide a safe work environment and protect your employees’ well-being, putting workplace safety equipment and policies in place saves your company a significant amount of money and time,” said Anthony Dublino, regional area manager for SafeRack.

The financial impact of workplace accidents is substantial. According to the National Safety Council, the cost per medically consulted injury in 2023 was $43,000, while the cost per death was $1,460,000. In other words, safety isn’t just the right thing to do — it’s a smart financial move too.

Here are some of the top reasons why it’s important to prevent workplace accidents:

- Improved morale: Nothing is more demoralizing than feeling like your company doesn’t care. A strong safety program shows your team that their health comes first and helps foster goodwill and employee happiness.

- Less absenteeism: Injured employees often miss work, and workers’ compensation claims can drag out absences even longer. Preventing accidents helps keep your team present and engaged.

- Higher productivity: When workers are sidelined, responsibilities fall on others or are left behind. Preventing accidents helps boost productivity, as healthy teams enjoy safe, optimized environments.

- Lowered workers’ comp rates: Fewer claims mean lower premiums, saving your business money.

- Improved reputation: A record of repeated injuries can damage your brand and hurt recruitment. A safe workplace shows your attention to detail and builds trust with both employees and customers, strengthening your company’s reputation.

- Less risk of OSHA fines: Frequent workplace accidents can incur OSHA penalties. Serious violations can bring fines of $16,550 per incident, and repeated violations can cost more than $165,000 each.

Important Note: This article provides general information about workplace safety and legal requirements. For specific situations involving workplace accidents, OSHA compliance, or workers’ compensation claims, consult with qualified safety professionals, occupational health experts, or legal counsel familiar with your industry and state requirements. Safety standards and legal obligations can vary significantly by location and industry sector.