Technology

It's impossible to a run a modern business without technology services. Our technology hub will guide you toward the software and tools necessary not just for everyday operations but also cost efficiency and long-term growth. Get recommendations for cutting-edge platforms, learn about the rise of AI-powered tech and find out what solutions can help you take your business to the next level.

Expert Advice, Tips and Resources for Upgrading Your Business Tech

The Best Technology Solutions for Your Growing Business

Trending Articles for Maintaining Your Business

Latest Small Business Technology Tips, Trends and Advice

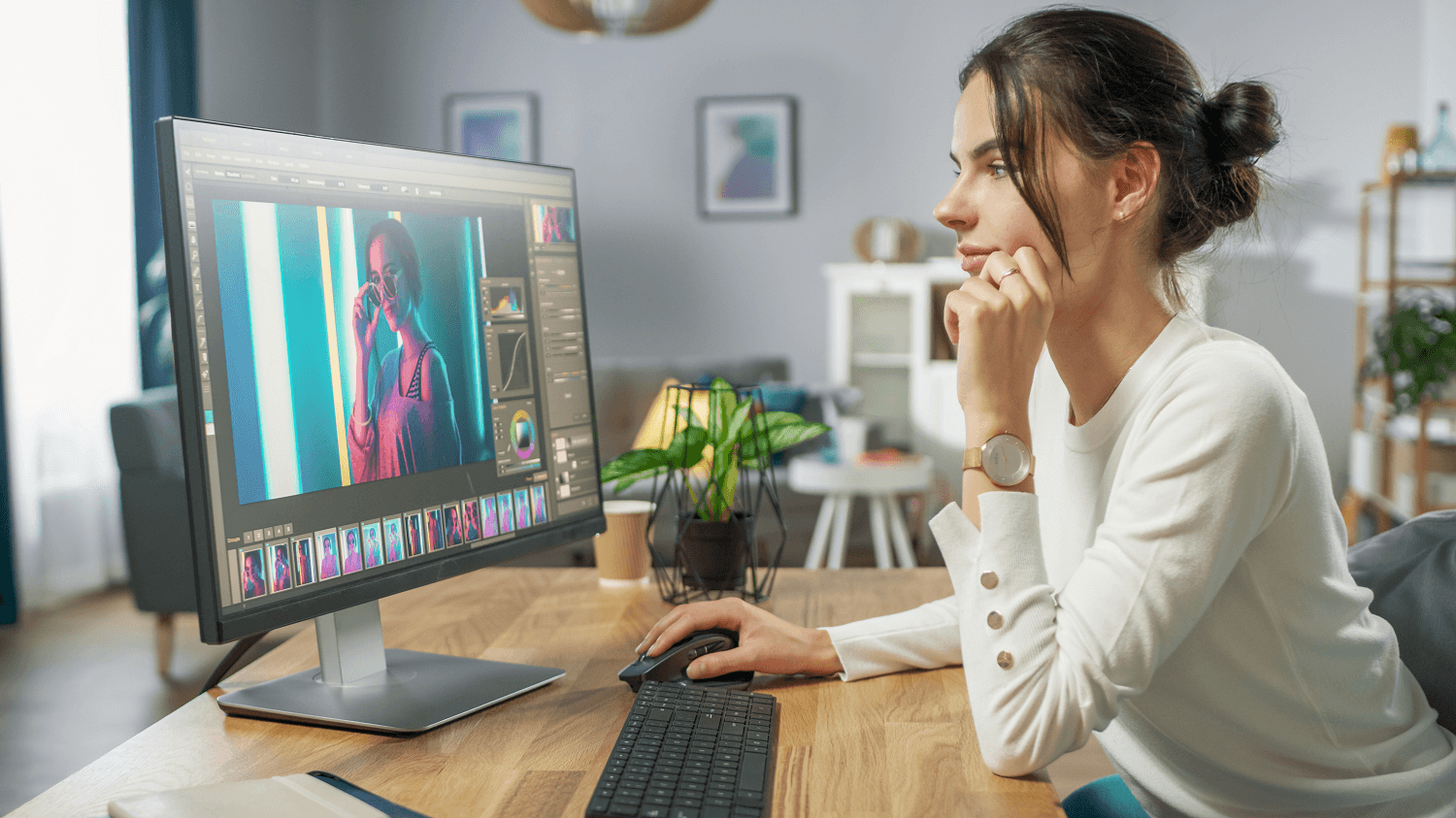

Photoshop remains supreme among editing software for photos, graphics and videos. Here's how and why to use Photoshop for your business.

This guide explains how to block and filter websites to restrict employee access to certain content on the company network.

GoTo Contact Center is top for small businesses with its user-friendly, omnichannel support on a budget, but lacks AI features and extensive integrations.

Most medical practices have switched to electronic recordkeeping, but there's still a place for paper.

Ransomware can hit businesses of any size. Here's how to keep your enterprise safe.

Zoom Phone offers internet-based phone services with feature-rich video conferencing tools. See pricing and how it stacks up to competitors.

Learn everything you need to know about virtual phone lines and how you can use one to optimize your business in a matter of moments.

This guide explains the differences between tethering and mobile hotspots, as well as which one might be better for your business.

Scams like phishing and business identity theft are rising fast, with businesses losing billions. Protect your company by training staff and securing data.

Twilio Flex is costly but ideal for businesses needing custom omnichannel communication solutions. Developers will love its customizability and robust API support.

Salesforce Service Cloud excels as top call center software by enhancing agent productivity and customer satisfaction with robust CRM integration and AI support.

RingCentral RingCX is top call center software for inbound teams, offering excellent analytics, training, and omnichannel routing, but AI features cost extra.

Five9 is the top call center solution for regulated industries, offering unmatched compliance and security. It's costly, lacks a free trial, and CRM integration costs extra.

DocuPhase excels in productivity with features like OCR, automatic file routing, and integrations, but lacks transparent pricing and can have a steep learning curve.

Viasat offers satellite internet with prioritized connections and rotating IPs for 96% of the U.S., ideal for rural businesses but slower than fiber options.

Domain registration doesn’t have to be expensive. Learn how to register your domain step by step and explore tips to ensure your domain name stays yours.

Revver, formerly Rubex by eFileCabinet, has excellent document storage capacity and workflow management tools. See features and pricing.

Many copiers, scanners and multifunction printers include automatic document feeders. Learn how automatic document feeders save you time and resources.

Test out one of these video conferencing platforms the next time you need to host a meeting.

Learn how GPS tracking tools can measure vehicles' idle time effectively to increase your company's productivity and profitability.

GPS fleet tracking software lets you track vehicles and monitor driving behaviors. Here's what to look for in a GPS fleet tracking system.

Small businesses spend 13.2% of IT budgets on cybersecurity. Experts suggest focusing on employee training, MFA,and practical defenses over costly tech.

Technology improves workplace communication through speed and access but can also hinder clarity and connection if it replaces thoughtful, in-person dialogue.

Here’s how scheduling automation can streamline your appointment booking process and make life easier for you and your small business’s clients.

Splashtop provides remote PC support solutions with fast connections and multiple levels of security.

CareCloud plugs your practice into a comprehensive platform for electronic health records (EHR), practice management and billing. This cloud-based software application works with nearly 40...

Unstable audio or video connections can make hosting a meeting difficult for any business. Here are the most common problems and their solutions.

These quick fixes allow you to clean and speed up your laptop so it runs like it did when you first bought it. See how to improve computer performance.

Compressing photos is easy. Learn how to compress JPEG images using a few simple tools.